The Louvre Abu Dhabi, designed by renowned architect Jean Nouvel, is one of the iconic UAE landmarks on Saadiyat Island, Abu Dhabi.

Working to a technical specification by the Engineers Burro Happold, Aegis was retained by the Main Contractor for the design, supply and implementation of a CP system to ensure the required 100-year design life for more than 3,000 H-piles and 90,000m2 of reinforced concrete surface area that are employed in the project’s complex sub-structure structure.

The CP system was commissioned in 2019. Aegis are currently responsible for managing the Operation & Maintenance of the complete CP system.

The Zayed National Museum, designed by renowned architect Foster & Partners, is another iconic museum being developed on Saadiyat Island in Abu Dhabi.

Working to a technical specification by the Engineer WSP, Aegis was retained by the Main Contractor for the design, supply and implementation of a cathodic protection system to ensure the required 100-year design life for 2,000 reinforced concrete foundation piles.

Phase I of the CP system was energised in 2022. Phase II is expected to be energised in 2023.

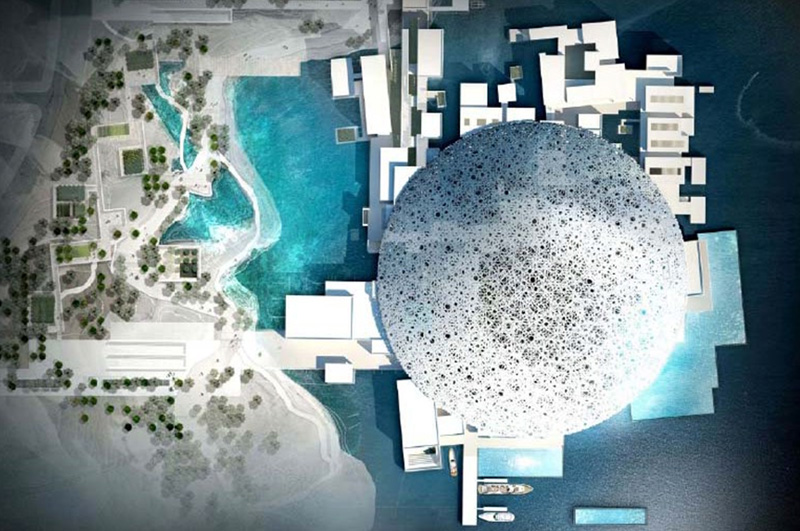

The world's tallest building demands a high-performance criteria and a long life. This project consists of an integrated corrosion monitoring and cathodic protection system for the reinforced concrete piles and hydrostatic slab that form the substantial foundation for this landmark structure.

Emaar Properties retained Aegis Technical Systems as the specialist contractor to execute the design, supply and implementation of the CP system. The objective of this system is to extend durability and service life by preventing chloride induced corrosion of the reinforcing steel by at least 100 years. The system was commissioned in 2008. Aegis have been Responsible for the O&M of the CP system since 2008.

A shopping center with a 170,000m2 footprint, and encompassing a marina, DFC City Core is built on reclaimed land in Dubai Creek with waterproof concrete and no membrane. Two levels of parking are below creek water level, with one carpark wall being the marina wall. The cathodic protection consists of an integrated corrosion monitoring and cathodic protection system for the reinforced concrete piles, the hydrostatic slab, and walls.

Aegis Technical Systems were retained by the Main Contractor as the specialist Sub-contractor to execute the design, supply and installation of the CP system. The objective of this system is to extend durability and service life by preventing chloride induced corrosion of the reinforcing steel by at least 40 years. This large-scale system incorporates more that 250 monitoring positions and over 1200 anodes. The system was commissioned in April 2006. Aegis have been Responsible for the O&M of the CP system since 2006.

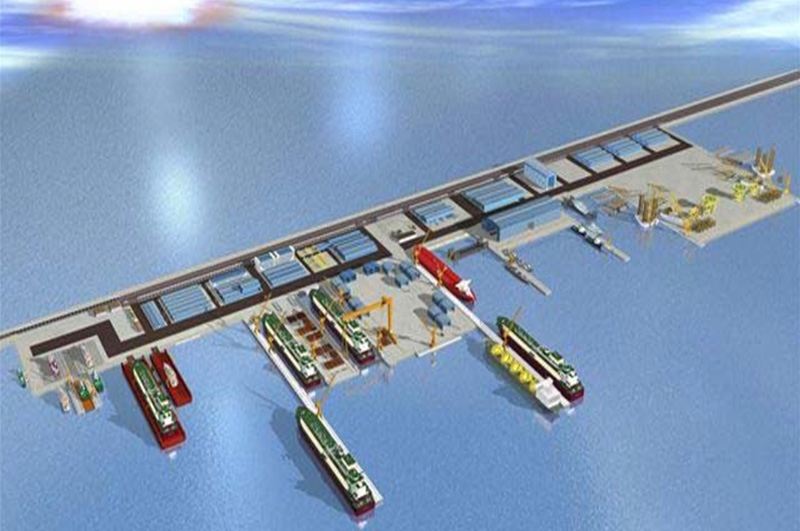

An extensive development including Ship Repair and Ship Construction Yard Piers No. 1 and No. 2, Quay No. 2, Unloading/Load-out Quay, Floating Dock Dolphins (Phases 1-5) was constructed from reinforced concrete and durability was to be assured using cathodic protection.

CTS worked with the Main Contractor for CP design, supply and implementation of various types of CP systems to ensure the reinforced concrete caissons and jetties are protected throughout the service life of the ship repair yard.

ADNOC retained CTS as a Main Contractor for design, supply, installation and commissioning of CP system for oil production, water injection and gas well casings in ADNOC BAB & Bu Hasa fields between 2014 and 2023.

A total of 318 numbers well casings have been provided with CP systems (142 No. in BAB Field & 176 No. in Bu Hasa Field). The ICCP system are powered using Transformer Rectifiers or in the absence of available AC power, Solar Powered Units.

Dolphin Energy's Dolphin Gas Project involves the production and processing of natural gas from Qatar's North Field and transportation of the gas by offshore pipeline to the UAE and Oman.

The Eastern Gas Distribution System (EGDS) comprising of approx. 770km of pipeline is used to transport natural gas onshore across the UAE and to Oman.

CIPS and DCVG surveys for 416km of the pipeline network within the UAE was awarded to CTS in 2021. The project was completed over a 6 month period.

This project was aimed at performing AC interference studies on the multiple pipelines paralleling various 132kV and 33kV OHL lines within the reservoir field in Marmul that is being developed by PDO.

The Main Contractor approached CTS to study the effect of AC interference on the new and existing pipelines that are routed both above and below ground in close proximity with OHL lines and propose mitigation measures as required. The project was completed in 2020.

CTS Europe Ltd has been retained by Calor Gas Ltd as the Main Contractor for routine monitoring services of Cathodic Protection Systems provided for over 15,000 Underground Storage Tanks distributed across the United Kingdom.

A team of technicians, certified by the Institute of Corrosion, conducts regular inspections in adherence to industry specifications, which require the inspections to be carried out at maximum 3-year intervals. Our technicians, supported by a group of experienced ICorr Specialists, have been carrying out these inspections since 2010.

By upholding our commitment to excellence and adhering to industry specifications, we safeguard the integrity and functionality of Calor Gas Ltd's extensive UST network, providing comprehensive protection for their valuable assets.

CTS Middle East LLC was retained by the Main Contractor for engineering, procurement, installation supervision, testing and commissioning for the cathodic protection works for the BAB Integrated Facilities Project, Abu Dhabi.

CP systems were designed for over 360km of pipelines, 250km of flowlines, 6km of piping, 250 well casings and 11 storage tanks (external and internal CP systems).

The project was completed in 2023. All CP systems were successfully commissioned thanks to the diligence of CTS’s design and site teams.